Fibre composite technology

Processing fibres and polymers into composites

Fibre composites have unique properties. Their excellent mechanical characteristics combined with low weight make them the material of choice for many lightweight applications. However, their processing requires appropriate technologies and experience to produce high-quality and innovative materials.

Contact: M.Sc. Florian Max

Phone: +49 921 55 7568

E-mail: florian.max@uni-bayreuth.de

Automated Fiber Placement (AFP) enables precise and repeatable manufacturing of composite materials. In this process, a slit tape is laid in multiple layers on top of each other and then cured. This method ensures high accuracy and consistency in the production of composite components.

Technical data

| Single spool | |

| Lay-up plate heatable | up to 180°C |

| Hot air heating | 50°C-400°C |

| Programmable gaps and overlaps | -99% to 99% of tape width |

| Continuously adjustable tape width | 1/8” to 1/2” |

| Lay-up speed | up to 400 mm/s |

| Contact pressure | up to 200 N |

| Continuously adjustable angle offset | |

| Maximum part width | 500 mm |

| Maximum part length | 500 mm |

Location: Neue Materialien Bayreuth GmbH

Contact: Florian Max, M. Sc.; Alexander Schmitt

Phone: +49(0)921 55 7568; +49(0)921 55 7563

Mail: florian.max@uni-bayreuth.de ; alexander.schmitt@uni-bayreuth.de

Test chamber volume [l] 100

Temperature [C°] -70 to 180

Heating/cooling rate [°C/s] 3

Humidity control

10 % to 98 % r.h. in the temperature range from 10 to 95°C

Location: University of Bayreuth

Interior [cm3] 75 x 100 x 75

Usable space volume [m3] 0.562

Maximum temperature [°C] 250

Location: University of Bayreuth

Technical data

| Type | Nodopur VS-2k |

| Serial Number | #2341 |

| Year of Manufacture | 2024 |

| Operating Pressure | 6-8 bar |

| Nominal Flow Rate | 1200 l/min |

| Machine Weight | 550 kg |

Location: Neue Materialien Bayreuth GmbH

Contact: Florian Max, M. Sc.

Phone: +49(0)921 55 75 68

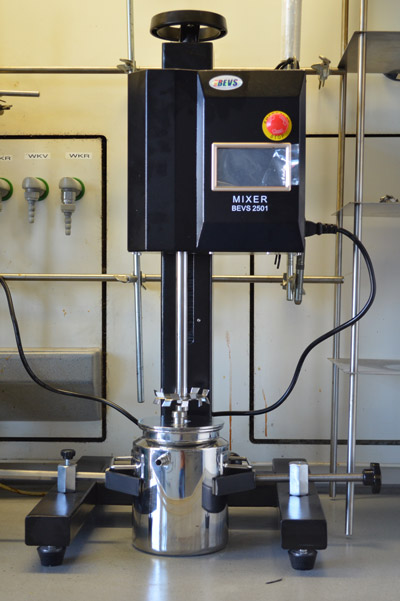

Speed [rpm] 30 – 9000

Batch size [l] 1.5

Motor power [W] 550

Processable materials

Suitable for ultra-fast agitation and dispersion of highly filled reactive resin and paint systems

Location: University of Bayreuth

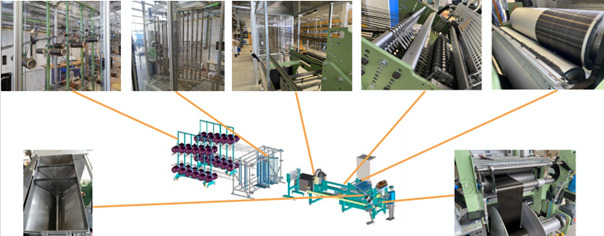

The chair has a UD 500 fiber spreading unit from Karl Mayer.

Carbon fiber and glass fiber rovings can be spread to defined areal weights. Furthermore, the system has a powder binder dosing unit for fixation of the spread tapes.

Technical data

| Maximum tapewidth | 10 inch (250 mm) |

| Maximum number of rovings | 24 |

| Roving Range | 12 K up to 60 K |

| Machine velocity | 1 – 20 m/min |

| Vibration frequency | 0 – 50 Hz |

| Deflection angle | 0 – 60 ° |

| Fiber tension | Adjustable up to 2000 cN per Roving |

| Temperature | Room temperature up to 200 °C |

| Powder binder unit | Available |

Location: Neue Materialien Bayreuth GmbH

Materials: -Towpreg winding -Wet winding -1 creel Max. winding diameter [mm] up to 254 Max. winding length [mm] up to 800 Max.. rotation speed [rpm] up to 100 Max. speed of the horizontal slide [cm/s] up to 152.4 Working fiber width [in] 1/8, 1/4, 1/2 NOL rings manufacturing [-] according to ASTM D 2290 Heating [°C] temperature-controllable from RT to 250 Location: Neue Materialien Bayreuth GmbH

Plate heating [°C] max. 200

Pressure range

0%

Volume of pressure vessel [l] 15

Features

– Heating plate 650 x 600 x 100 mm

– Aluminium worktop, thickness: 15 mm

– High pressure hose heatable up to 150 °C

Location: University of Bayreuth

Maximum pressure [ bar] 8

Maximum temperature [°C] 180

Maximum heating rate [°C/min] 3

Feeding diameter [mm] ø 670

Feeding length [mm] 800 mm

Monitoring of 4 component temperatures

Monitoring of 4 vacuum lines

Location: Neue Materialien Bayreuth GmbH

Injection pressure

0%

Post pressure

0%

Resin/hardener tank temp. [°C] 150

Mixing ratio resin/hardener 100/3 to 100/100

Features

Electric agitator / vacuum pump

Location: Neue Materialien Bayreuth GmbH

Plate size [mm2] 300 x 300

Max. press force [kN] 200

Max. sheet temperature [°C] 300

Heating rate [K/min] up to 15

Cooling rate [K/min] > 30

Special feature

Test press equipped with a load cell for precise control of press force

Location: Neue Materialien Bayreuth GmbH

Pressing area [mm] 600 x 600

Pressing force [kN] 1000

Cylinder stroke [mm] 450

Working temperature [C°] 25 – 250

Max. heating/cooling rate [C°/min] 7

Temperature control medium

Heat transfer oil

Location: Neue Materialien Bayreuth GmbH

The process is unique as it allows direct lamination in one step. The system consists of a single-screw extruder and a special laminating unit. This allows copper foils to be laminated directly onto a substrate material. The extruded semi-finished product can be further processed in the electrical industry. Furthermore, it is possible to impregnate glass and carbon fibre mats directly using the system.

| Screw diameter laboratory kneader [mm] | 30 |

| L/D | 20 |

| Speed max. [1/min] | 180 |

| Torque max. [Nm] | 94 |

| Material throughput [kg/h] | 4 – 25 |

| Processing temperatures [°C] | up to 450 |

| Heating system | electric |

| Cooling | Air |

| Fittings | Calender with haul-off unit |

| Location | NMB Modul 1 – Bayreuth |

| ContactPhone | Markus Schirmer+49 921 / 55 7550 od.7551 |

Working width [cm] max. 30

Web speed [m/min] up to 10

2 calenders [°C] temperature-controllable from 1 to 250

B staging temperature [°C] 250 (2 separately temperature-controlled heating plates)

Fibres / semi-finished fibres

– up to 32 rovings; in-line spreading unit available

– textile semi-finished products (woven fabrics, scrims, fibre mats) up to 30 cm wide

Matrix materials

duromer, solvent-free resin systems in the viscosity range from 10 to 50,000 mPas

Impregnation technology

Foulard (immersion bath), comma blade, indirect roller application

Location: Neue Materialien Bayreuth GmbH

Features

Recording of the material temperature during cross-linking

Oil bath for temperature control

Temperature recording

Determination of relative viscosity

Location: University of Bayreuth

Speed [rpm] 510 – 3500 (stepless)

Mixing time[sec] 5 – 300

Container sizes [ml] 185, 60, 25, 12

Location: University of Bayreuth

Mixing capacity [g/lb.] Up to 800/1.76

Mixing volume [ml/gal] Up to 750/0.19

Mixing Speed [rpm] 800 – 1950

Mixing time [min] 10

Programs [ml] 20

Mixing steps/programs 5

Vacuum Yes

Minimum pressure [mbar] 0

Location: University of Bayreuth

Working width [cm]

45

Minimum gap width [µm]

5 (gap-controlled), < 5 (force-controlled)

Throughput per hour [l]

0.5 to 60

Process temperature [°C]

Room temperature up to 60

Fittings

Heating unit

Processable materials

Modified and filled resin systems, elastomers;

Solvent-based systems can be processed

Location: Neue Materialien Bayreuth GmbH

max. frequency in echo mode [MHz] 16 in water

max. frequency in through-transmission mode [kHz] 120 in air

max. amplification [dB] 90

min. defect size [mm] 5 (in air)

0.25 (in water)

Testing options

A-, B- and C-scan, 3D scan

Software for quantitative evaluation of delamination areas

Location: Neue Materialien Bayreuth GmbH

Interior volume [l] 49

Temperature [C°] 20-200

Vacuum [mbar] 1-1013

Location: University of Bayreuth