Further analytics

Exploring more properties of polymeric materials

In addition to the characterisation methods described below, we have a range of other methods at our disposal through our university network and our cooperation with Neue Materialien Bayreuth GmbH. This allows us to react very flexibly to new questions in order to advance ongoing research projects with necessary effectiveness.

Contact: Christian Brütting, M.Sc.

Phone: +49 921 55 7482

E-mail: Christian.Bruetting@uni-bayreuth.de

The quality of plastic products crucially depends on the water content of the raw material during processing.

To determine the water content of plastics according to ISO 15512 (method B), we use the automatic Karl Fischer C30S coulometer with the Stromboli oven sample changer for up to 14 samples.

The coulometer offers a very precise determination of water content (up to 5 %) using only very small sample weights. In addition, the analysis of a wide variety of samples such as liquids, powders, granulates, foam beads, etc. is possible.

The analysis is carried out in the following steps:

- Heating the sample (blank sample)

- Transfer of escaping water into the measuring cell

- Titration of transferred water

- Determination of water content via the mass of used titration solution

Sample weight [g] 0.1 – 10

Water content [ppm] 1 – 50,000

Oven temperature [°C] 50 – 300

Sample number

Up to 14 per series

Type of sample

Liquid, powder, granulate, foam etc.

Other features

Individual method design

Location: University of Bayreuth

Measuring geometry 0°

Measuring aperture diameter [mm] >25.4

Measuring field diameter [mm] 18

Colour sensitivity

in spectral adjustment to CIE standard spectral value function y

standard illuminant CIE-C

Measuring ranges

Transmission [%] 0-100

Haze [%] 0-100

Clarity [%] 0-100

Location: University of Bayreuth

For measuring the open cell and compressibility of foams according to ASTM D-2856. Single or multiple measurements with averaging possible. Correction option for open cells on cut surfaces.

3 sample cells [cm3] 10, 50, 135

Gas pressure [psi] 2 to 20 (approx. 0,14 to 1,48 bar) above normal pressure

Location: University of Bayreuth

Contact: M. Sc. Marcel Dippold

E-mail: marcel.dippold@uni-bayreuth.de

In addition to pure impedance analysis up to 3 GHz, the Agilent E4991A RF impedance meter allows in particular the determination of complex permittivity over a continuous frequency range from 1 MHz to 1 GHz. Using a temperature chamber, the influence of temperature can also be taken into account.

Frequency range: MHz – 3 GHz (impedance measurement); 1 MHz – 1 GHz (permittivity)

Temperature range [°C]: RT-250

Measurement modes

Impedance analysis, parallel plate permittivity measurement

Sample

Thickness approx. 1 – 8 mm, diameter ≥ 25 mm

Location: University of Bayreuth

Measuring frequencies: 5 and 10 GHz

Temperature range [°C]: RT-80

Measurement mode

Split-Post Dielectric Resonator

Sample

Flat specimens with plane-parallel sides; max. thickness 1.9/0.9 mm (5/10 GHz), min. diameter/edge length 30/22 mm (5/10 GHz)

Location: University of Bayreuth

Total capacity [l] 2.5

Speeds [l/min] up to 1500

Power [kW] 2.2

Mixing tool speed [l/min] 400 – 4000

Features

Mixing tank with double jacket for cooling with water, cooling jacket with 2 bar water pressure.

Year of manufacture

2002

Location: Neue Materialien Bayreuth GmbH

Permeation

The following options are available for measuring the permeability of films and packaging:

- Measurement of oxygen transmission

- Measurement of water vapour transmission

- Measurement of carbon dioxide transmission

- Films certified according to the NIST guidelines are available for calibrating devices.

OX-TRAN ® 2/21

The permeation measuring device OX-TRAN 2/21 with 2 measuring cells measures the transmission of oxygen and thus the barriers of flat materials and packaging. The coulometric sensor used in the modules is an absolute oxygen sensor. This means that this patented sensor does not need to be calibrated to measure permeation.

PERMATRAN-C ® 4/41

The PERMATRAN-C 4/41 with 2 measuring cells measures the transmission of carbon dioxide and thus the barriers of flat materials and packaging.

PERMATRAN-W ® 3/33

The PERMATRAN-W 3/33 with 2 measuring cells measures the transmission of water vapour and thus the barriers of flat materials and packaging.

OX-TRAN ® 2/21

Carrier gas nitrogen (N2)

Test gas oxygen (O2)

Temperature range [°C] 5 – 50 ± 0.5

Humidity [%] 35 to 90 RH ± 3 RH, 0 RH

Measuring range

Flat materials 0.005 – 155,000 cm3/m²/day, packaging 0.00005 – 1.550 cm3/pckg/day

PERMATRAN-C ® 4/41

Carrier gas nitrogen (N2)

Test gas carbon dioxide (CO2)

Temperature range [°C] 5 – 50 ± 0.5

Measuring range

Flat materials 1 – 800,000 cm3/m²/day, packaging 0.005 – 775 cm3/pckg/day

PERMATRAN-W ® 3/33

Carrier gas nitrogen (N2)

Test gas water vapour (H2O)

Temperature range [°C] 5 – 50 ± 0.5

Humidity [%] 35 to 90 RH ± 3 RH, 100 % RH (HPLC water)

Measuring range

Flat materials 0.005 – 1000 g/m²/day, packaging 0.00003 – 0.5 g/pckg/daya

Location: University of Bayreuth

Capacity [l/min] 300 – 1740

Blasting nozzle [mm] 6 – 10

Pressure 3 – 10 bar

Year of manufacture

2002

Location: University of Bayreuth

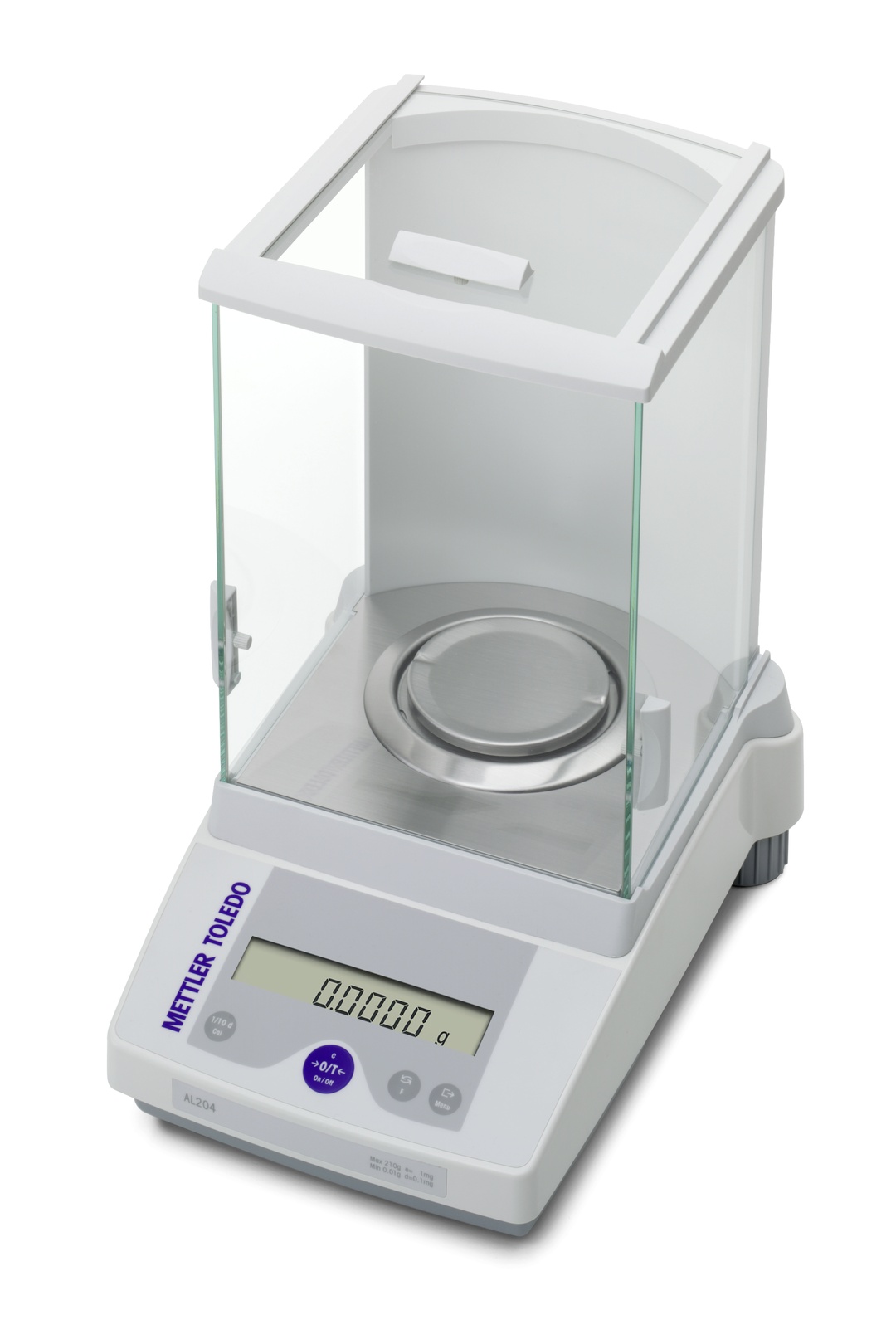

In addition to the standard weighing procedure, the AG245 analytical balance by Mettler Toledo is particularly well suited for piece counting, percentage weighing, formulation, and dynamic weight recording. With the help of the density kit for AG balances, buoyancy measurements, and thus density determinations according to the Archimedes principle, are also possible.

Readability [mg] 0.1mg/0.01

Maximum load [g] 210/41

Repeatability (s) [mg] 0.1/0.02

Linearity [mg] ±0.2/±0.03

Settling time [s] 3/15

Temperature drift [ppm/°C] ±1.5

Long-term drift [%] ±0.003

Location: University of Bayreuth

Contact: M. Sc. Christian Brütting

Phone: +49 921 55 7482

max. frequency in echo mode [MHz] 16 in water

max. frequency in through-transmission mode [kHz] 120 in air

max. amplification [dB] 90

min. defect size [mm] 5 (in air)

0.25 (in water)

Testing options

A-, B- and C-scan, 3D scan

Software for quantitative evaluation of delamination areas

Location: Neue Materialien Bayreuth GmbH