Injection moulding

Producing moulded parts quickly and easily

Injection moulding can be used to produce moulded parts ranging from a few milligrams to kilograms in mass. Even complex geometries can be realised fully automatically in a single operation. The process is also characterised by high reproducibility and a low rate of rework. For this reason, injection moulding is currently the most important technology for producing moulded parts out of thermoplastics.

We have a large number of injection moulding machines at our disposal. The clamping force of the machinery ranges from 50 to 250 tonnes. The focus is on special processes such as foam injection moulding, and the processing of long-fibre reinforced thermoplastics or high-temperature thermoplastics. In addition to conventional injection moulding for the production of test specimens, we can draw on the machinery of Neue Materialien Bayreuth GmbH and the special injection moulding processes available there (https://www.nmbgmbh.de/verfahren/spritzgiesssonderverfahren/).

Contact: Sebastian Gröschel

Phone: +49 921 55 7420

E-mail: sebastian.groeschel@uni-bayreuth.de

The cost-efficient production of injection moulded parts requires the shortest possible cycle times, which are in the range of just a few seconds for mass-produced articles.

For this purpose, we use the hybrid injection moulding machine Arburg Allrounder 470 H 1000 – 170, which combines electric speed with hydraulic power.

The Arburg 470 H 1000 – 170 is the ideal injection moulding machine wherever short cycle times and high precision with very thin walls are required. In addition, thanks to its installed ProFoam unit, the machine has the option of thermoplastic foam injection moulding (TSG). This combination allows, for example, foamed thin-walled articles to be produced in very short cycle times.

Clamping unit servo-electric

Clamping force [kN] 1,000

Clear distance between tie bars [mm] 470

Minimum installation height [mm] 250

Maximum platen spacing [mm] 850

Maximum processing temperature [°C] 450

Physical blowing agent N2 or CO2

Injection unit 170

Screw diameter [mm] 30

Effective screw length [L/D] 20

Maximum injection volume [cm3] 85

Maximum injection pressure

0%

Maximum shot weight [g PS] 77

Maximum loading pressure [bar] 50

Location: University of Bayreuth

- Movable turntable with vertical centre plate (rotating/ oscillating)

- 2C operation with parallel injection units with bolt shut-off nozzle

- Precision embossing, breathing (injection embossing EXPERT)

- Core mould: 2C plate variotherm with plunge edge (200 x 400 mm)

- Core pulls: FAP (1 x pneumatic, 2 x hydraulic)

- BAP (1 x pneumatic, 2 x hydraulic)

- MP (2 x pneumatic, 4 x hydraulic)

- Standard 1C operation with ejector dummy

- Linear system for part removal

- Foam injection moulding (chemical, MuCell)

- 2K overmoulding

- Injection-compression moulding

- Variotherm mould temperature control

- Long-fibre reinforced thermoplastics (LFT pellets)

Clamping force [kN] 4,500

Clear tie bar spacing [mm] 800 x 900

Minimum installation height [mm] 350

Injection unit 1 [mm] 60 (MuCell)

Injection unit 2 [mm] 60

Max. Injection weight [g/hp] 700 each

Max. injection pressure [bar] 2,000

Maximum processing temperature [°C] 450

Property of Neue Materialien Bayreuth GmbH

Location: Neue Materialien Bayreuth GmbH

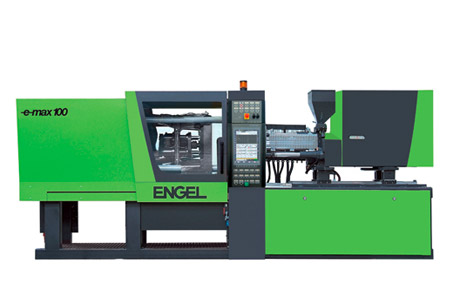

- Tie-bar closing unit, servo-electric, with 2-train knee lever.

- Valve gate nozzle

- Temperature monitoring for both clamping platens

- Freely programmable interfaces (4 inputs, 4 outputs)

- TFT touch-screen colour monitor

Clamping force [kN] 500

Clear tie bar distance [mm] 370 x 320

Minimum installation height [mm] 150

Screw diameter [mm] 150

Screw length [mm] 30

L/D 20.5

Maximum barrel temperature [°C] 350

Location: Neue Materialien Bayreuth GmbH