Microscopy & 3D-Scanner

Discovering material structures

Through our imaging analysis techniques, we explore the micro- and nanostructure of materials. Our tomographic capabilities even give us a three-dimensional insight into the structure. Thanks to our application-oriented and industry-related research activities, we can draw on commensurate experience. This includes preparative sample preparation and computer-assisted evaluation as well as post-processing.

Contact: Annika Pfaffenberger

Phone: +49 921 55 7503

E-mail: annika.pfaffenberger@uni-bayreuth.de

Electron source tungsten cathode

Accelerating voltage [kV] 0,5 bis 30

Resolution in SE image [nm] 3 at 30 kV, 15 at 1 kV

Magnification range x5 to x300 000

Specimen stage (travel) [mm] X: 80, Y: 40, Z: 6 to 45

Detectors

Secondary and backscatter electron detector

Resolution [nm] 0.2 (line), 0.29 (point), at 200 kV

High voltage [kV] 120; 160; 200 (variable)

Nominal voltage [eV] 0 – 2500 (step size 0.2 eV)

Cathode thermal LaB6 cathode

Koehler radiation system four lenses

Focus length [mm] 3

Spherical aberration constant cs [mm] 2.2

Chromatic aberration constant cc [mm] 2.2

Astigmatism [µm] <1

Smallest focusing step [nm] 15

Spectrometer type Omega

Isochromatic [eV] Energy resolution (reduced irradiation) ± 0.65

Distribution [µm/eV] 0.8 (energy distribution plane), 0.3 (image plane)

Image recording

Negative film (3,25″ x 4″), Gatan Ultrascan 1000 CCD camera with Gatan GMS image processing

Magnification 6,3 to 40 fach

Features

Digital and analogue image processing

Test method

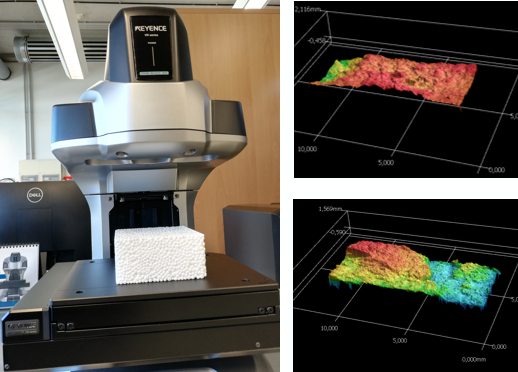

Surface topography, measuring microscope

Automated microscope with high-resolution Leica DFC450 digital camera and LAS software for image processing.

Objectives: 5x, 10x, 20x, 50x (plus 10x)

Methods: incident light (brightfield, polarisation), transmitted light (brightfield, polarisation)

Motorised high-performance focusing drive with small step size of 10 nm for capturing image stacks in Z-direction

- Visualisation of samples with high roughness with outstanding image sharpness

- Quantification of height differences on the sample surface

- Automatic combination of overlapping images through stitching function

Can be used with a Mettler-Toledo FP82HT hotstage (in combination with a 20x objective, temperature range: RT to 375 °C).

Accuracy of the hotstage: RT to 100 °C ± 0.4 °C

100 to 200 °C ± 0.6 °C

200 to 300 °C ± 0.8 °C

Phone: +49 921 55 75 03

E-mail: annika.pfaffenberger@uni-bayreuth.de

Location: University of Bayreuth

Sputter material gold

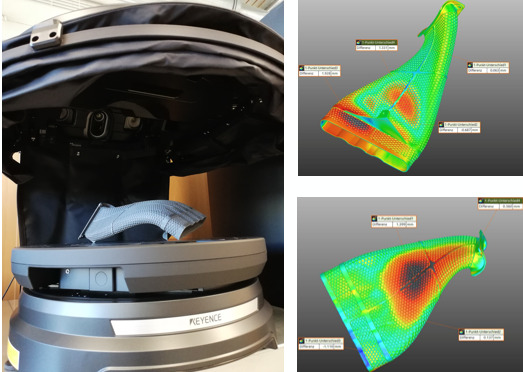

Scan size [mm] 230 x 240 x 300

Light source LED (multicolor)

Repeatability [µm] 0,5

Measurement accuracy [µm] ±2

Technology

Automated roughness detection

Field-of-view

Low: 12x, 25x, 38x, 50x

High: 40x, 80x, 120x, 160x

Scan size [mm] 580 x 300 x 200

Light source LED (multicolor)

Repeatability [µm] 2

Measurement accuracy [µm] ±10

Technology

Automated 3D-scanning

Rotation mechanism 360°

Tilt mechanism up to 45°