Thermoset processing

Creating cross-linked polymers

Due to their reactive processing, thermoset materials require specialized manufacturing technology. This begins with the mixing of the initial formulation and extends to the cross-linking or shaping and post-treatment. We have a wide range of modern equipment at our disposal to handle a variety of thermoset moulding compounds and materials safely and efficiently. These include epoxy resins, polyurethanes, polyesters, acrylates, and many more. The focus is particularly on the production of fibre composites with thermoset matrix systems.

Contact: M. Sc. Michael Hoffmann

Phone: +49 921 55 7472

Mail: Michael.Hoffmann@uni-bayreuth.de

General information:

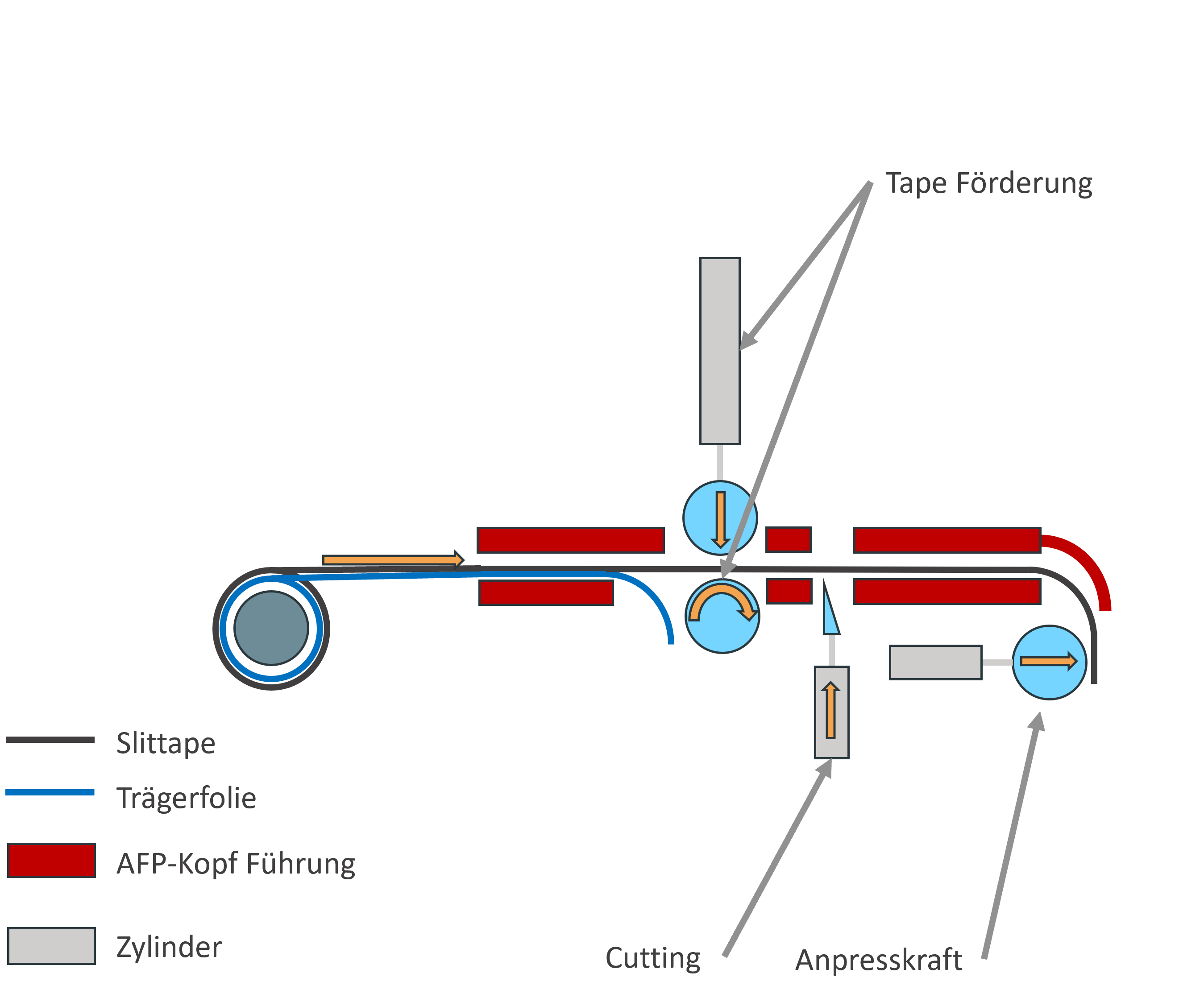

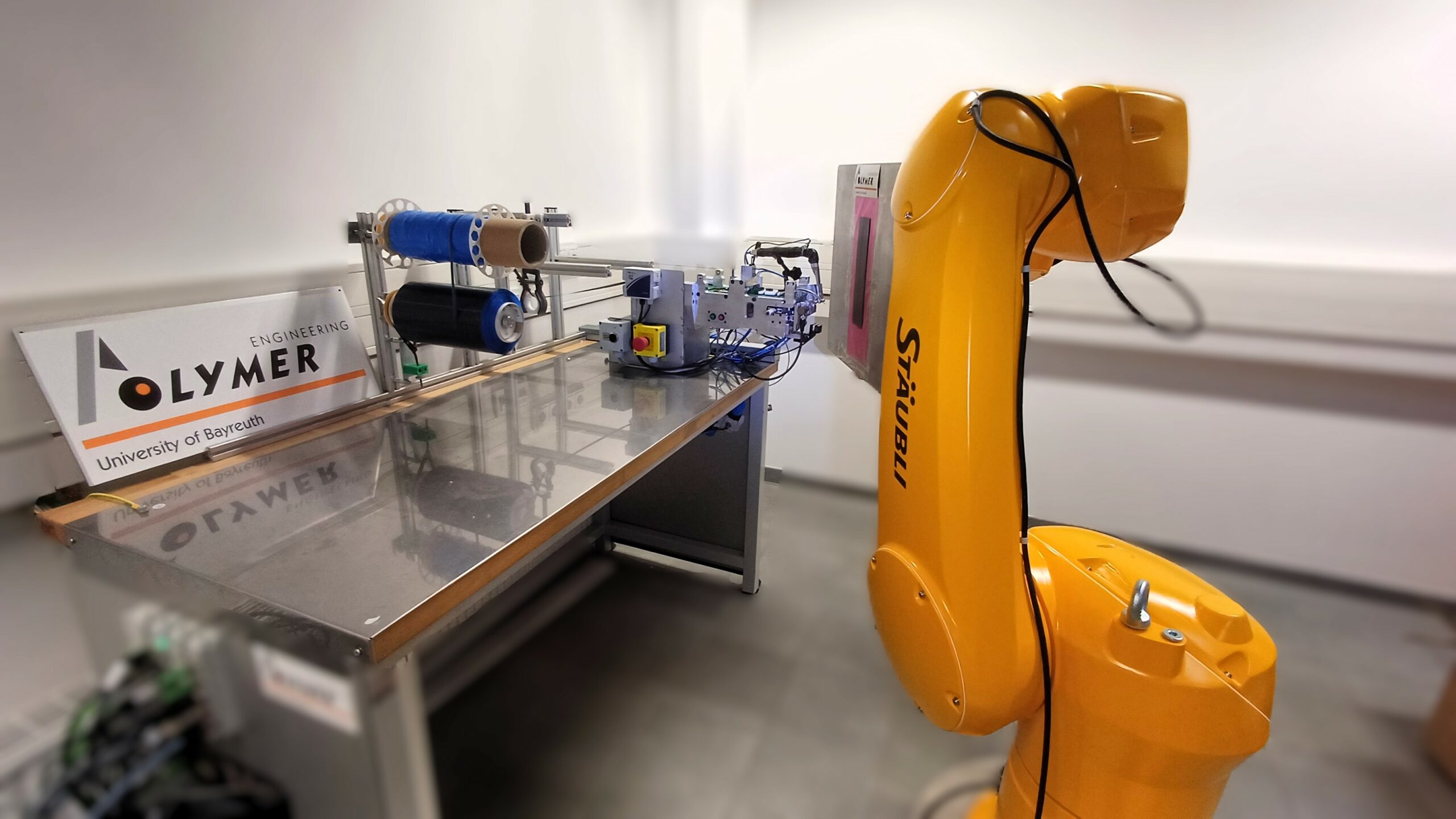

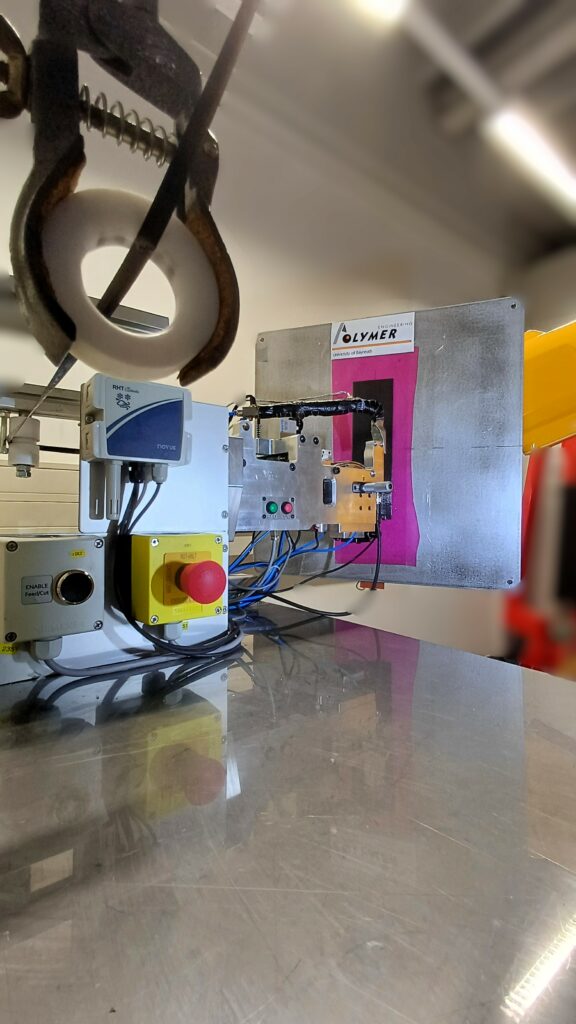

Robot model Stäubli TX2-160

Single spool variant

Tape/head stationary

Deposition plate: 500 x 500 mm for 2D laminates

Deposition plate heating: Up to 180 °C

Hot air heating: Up to 400 °C

Press force monitoring

User-friendly and fast setup

Slit tape width: Adjustable from 1/8″ to 1/2″

Deposition speed: Up to 400 mm/s

Press force: Up to 200 N

Component width: Max. 500 mm, adjustable

Component length: Min. 200 mm to max. 500 mm, adjustable

Number of component layers: Adjustable

Angle offset per layer: Infinitely adjustable

Location: NMB

Contact: Florian Max, M. Sc.

Phone: +49 921 55 7568

The Zehntner ZAA 2300 made by Proceq is an universal thin film applicator. The bed is heated, and so higher viscosity system can be handled.

Films can be made up to the length of 400 mm and 300 mm width.

Analog display

Length of the film: up to 400 mm

Width of the film: up to 300 mm

Temperature of the heated bed: 150 °C

Drawing speed: ZAA2300 1 mm/s – 90 mm/s

Location: University of Bayreuth

Contact: Michael Hoffmann, M. Sc.

Phone: +49 921 55 74 72

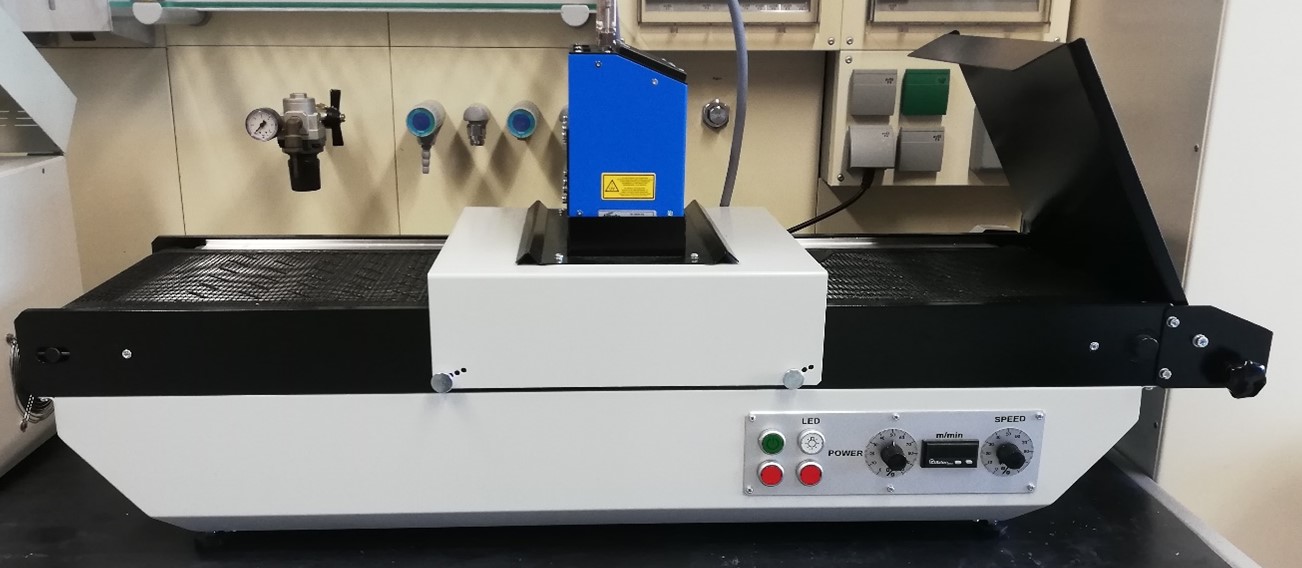

| Conveyor belt width | 30 cm |

| Conveyor belt length | 105 cm |

| Maximum exposure width | LED Spot (405 and 365 nm) à 21 cm

Powerline 405 nm à 25 cm |

| Maximum intensity | LED Spot (405 and 365 nm) à 3.000 mW/cm2

Powerline 405 nm à 16.000 mW/cm2 |

| Velocity | 0,1 – 2,0 m/min |

| Existing specimen moulds | DMA, Tensile, 3-Point-Bending, Fracture Toughness KIC |

Location: University of Bayreuth

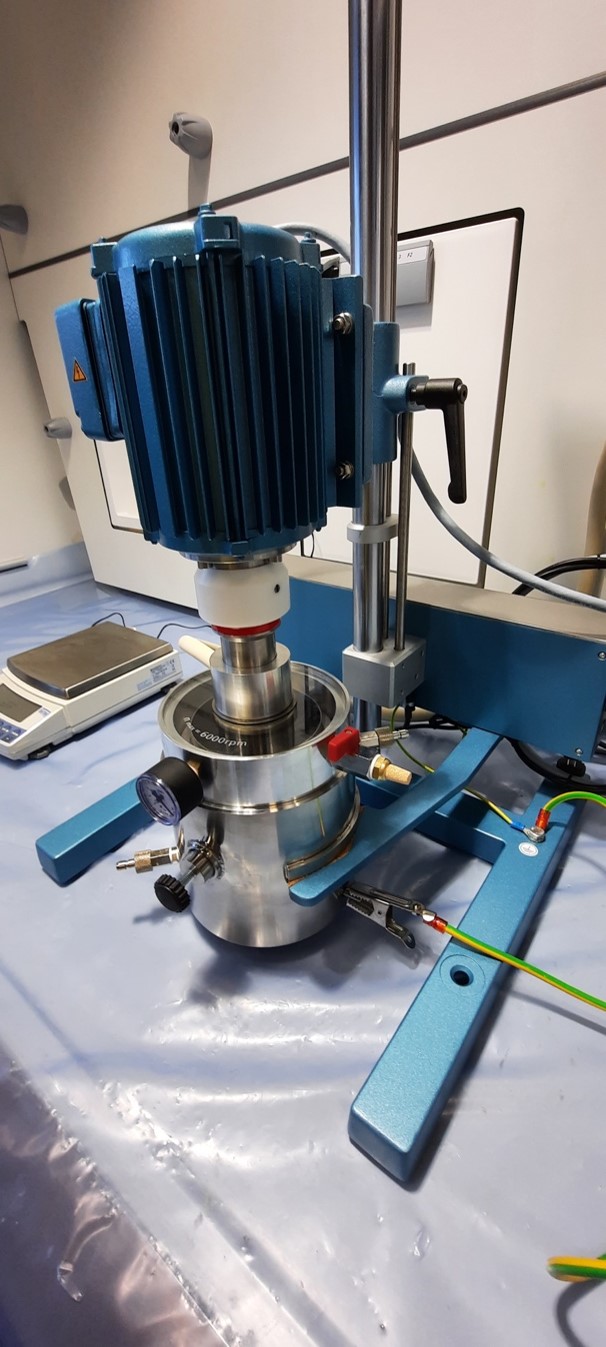

Rotation speed: 0-12.000 U/min

Power: 0,75 kW

Speed: 0-12.000 U/min

Location: University of Bayreuth

Working Width [cm] max. 30

Belt Speed [m/min] bis zu 10

2 Calenders [°C] of which one can be temperedup to 250

B-Staging-Temperature [°C] 250 (2 separated Heating Plates)

Fibres / semi-finished Fibres

– Up to 32 rovings; in-line spreading unit available

– Textile semi-finished products (woven fabrics, scrims, fibre mats) up to 30 cm wide

Matrix Materials

Duromers, solvent-free resin systems in the 10 to 50,000 mPas viscosity range

Impregnation Technologies

Foulard (immersion bath), comma blade, indirect roller application

Location: Neue Materialien Bayreuth GmbH

Working Width [cm] 45

Minimum Gap Width [µm] 5 (Gap-controlled), < 5 (Force-controlled)

Throughput per Hour [L] 0.5 to 60

Process Temperature [°C] RT to 60

Additional Equipment

Heating Unit

Processable Materials

Modified and filled resin systems, elastomers;

Solvent-based systems can be processed

Location: Neue Materialien Bayreuth GmbH

Injection Pressure [bar] 20

Post pressure [bar] 70

Resin-/Hardener Tank Temp. [°C] 150

Mixing Ratio Resin / Hardener 100/3 to 100/100

Features

Electric Agitator / Vacuum Pump

Location: Neue Materialien Bayreuth GmbH

Speed [rpm] 510 – 3500 (stufenlos)

Mixing Time [sek] 5 – 300

Container Sizes [ml] 185, 60, 25, 12

Location: University of Bayreuth

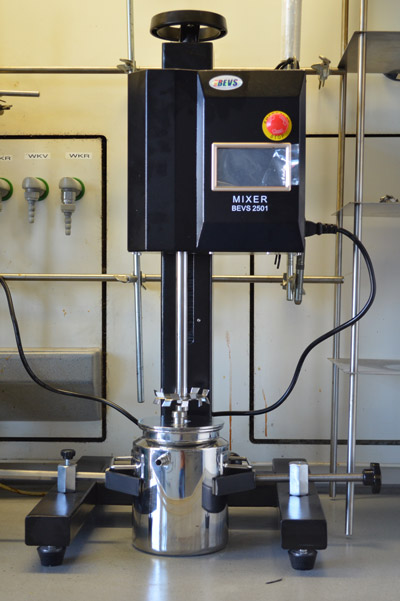

Speed [rpm] 30 – 9000

Batch Size [L]1,5

Power [W] 550

Processable Materials

Suitable for ultra-fast agitation and dispersion of highly filled reactive resin and paint systems

Location: University of Bayreuth

Plate Heating [°C] max. 200

Pressure Range [bar] 0-20

Volume of Pressure Vessel [L] 15

Features

– Heating Plate 650 x 600 x 100 mm

– Aluminium Worktop, Thickness: 15 mm

– High Pressure Hose heatable up to 150 °C

Location: University of Bayreuth

Platte Size [mm2] 300 x 300

Max. Pressure Force [kN] 200

Max. Platte Temperature [°C] 300

Heating Rate [K/min] up to 15

Cooling Rate [K/min] > 30

Special Features

Test press equipped with a load cell for precise control of the press force

Location: Neue Materialien Bayreuth GmbH

Pressure Surface [mm] 600 x 600

Pressure Force [kN]1000

Cylinder Stroke [mm] 450

Working Temperature [C°] 25 – 250

Max. heating-/hooling Rates [C°/min] 7

Temperature Controll Medium

Thermo Oil

Location: Neue Materialien Bayreuth GmbH

Max. Frequency in Echo Mode [MHz] 16 in Water

Max. Frequency in Through-Sound Mode [kHz] 120 in Air

Max. Amplification [dB] 90

Min. Defect Size [mm] 5 (in Air) / 0.25 (in Water)

Testing Options

A-, B- und C-Scan, 3D-Scan

Software for quantitative evaluation of areas of delamination

Location: University of Bayreuth

Features

Recording of material temperature during cross-linking

Oil bath for temperature control

Temperature recording

Determination of relative viscosity

Location: University of Bayreuth

Features

Recording of material temperature during cross-linking

Oil bath for temperature control

Temperature recording

Determination of relative viscosity

Location: University of Bayreuth

Volume [cm3] 75 x 100 x 75

Usable Volume [m3] 0,562

Maximum Temperature [°C] 250

Location: University of Bayreuth

Inner Volume [L] 49

Temperature [C°] 20-200

Vacuum [mbar] 1-1013

Location: University of Bayreuth

Test Chamber Volume [L] 100

Temperature [C°] -70 bis 180

Heating- / cooling Rate [°C/s] 3

Humidity Control

10 % to 98 % relative humidity in a 10 to 95°C temperature range

Location: University of Bayreuth